| Pearson 10M Electric Drive Cooling System |

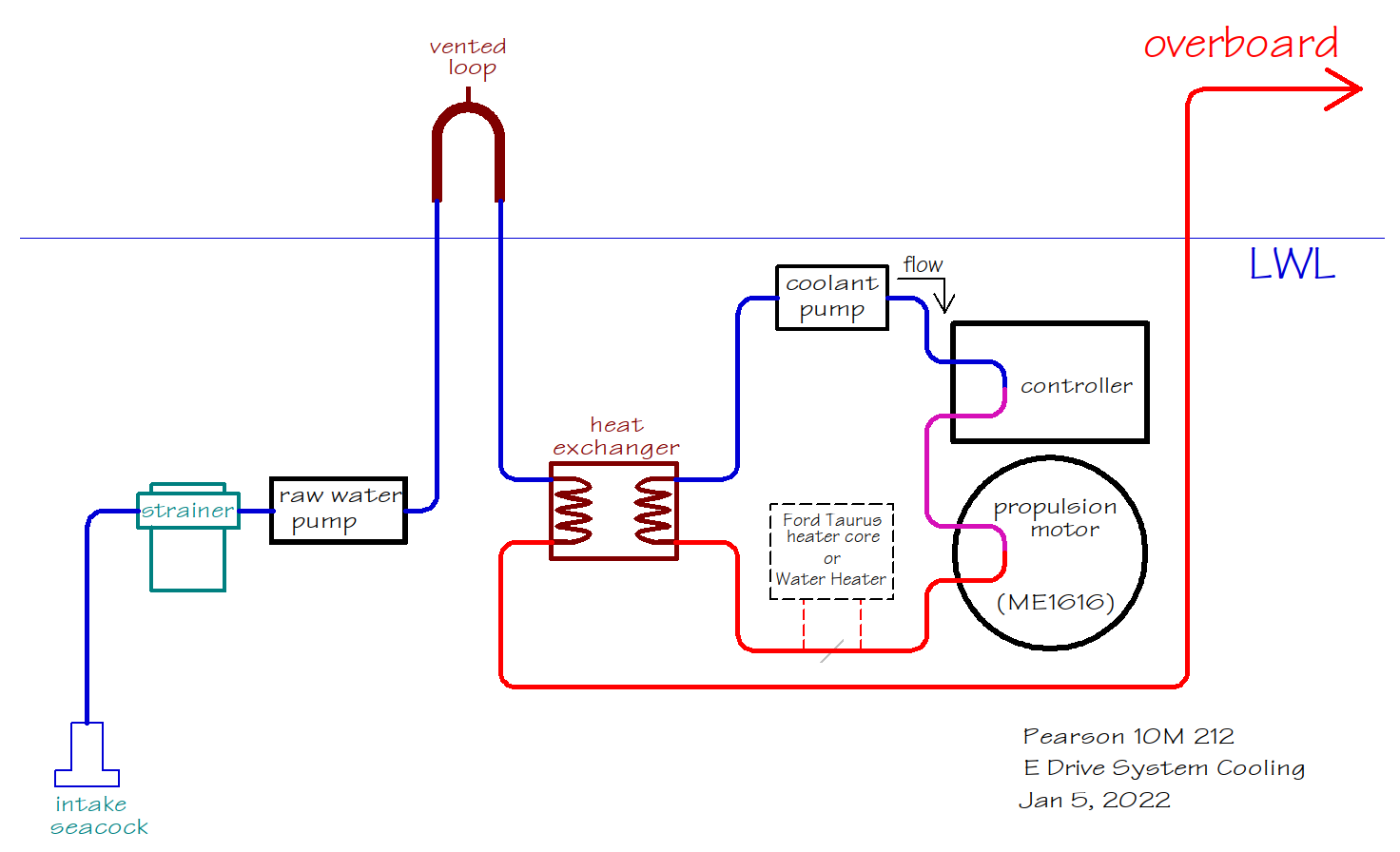

To run at sustained high speeds the electric drive system needs to be cooled. The cooling system is a closed loop with coolant (glycol) circulated through the controller cooling plate, the motor and a heat exchanger by a 12V pump. The pump is controlled by the Sevcon motor controller with a relay. The controller turns the coolant pump on when the motor reaches 122F and off at 105F. The heat exchanger transfers the coolant heat to raw sea water that is pumped by another 12V pump from a seacock in the bottom, through the raw water side of the heat exchanger and then overboard. Circulating the coolant with the raw water pump off is enough to keep the system at an acceptable temperature up to about 5.5 knots in normal operation. Faster than that and the raw water pump is turned on. I plan to add an air-cooled heat exchanger (heater core from a Ford Taurus) to the coolant loop to raise the speed I can make before needing the raw water pump.

To run at sustained high speeds the electric drive system needs to be cooled. The cooling system is a closed loop with coolant (glycol) circulated through the controller cooling plate, the motor and a heat exchanger by a 12V pump. The pump is controlled by the Sevcon motor controller with a relay. The controller turns the coolant pump on when the motor reaches 122F and off at 105F. The heat exchanger transfers the coolant heat to raw sea water that is pumped by another 12V pump from a seacock in the bottom, through the raw water side of the heat exchanger and then overboard. Circulating the coolant with the raw water pump off is enough to keep the system at an acceptable temperature up to about 5.5 knots in normal operation. Faster than that and the raw water pump is turned on. I plan to add an air-cooled heat exchanger (heater core from a Ford Taurus) to the coolant loop to raise the speed I can make before needing the raw water pump.

Without cooling the ME1616 motor can run continuously at 140 amps. At 48V that's 6,700 watts which works out to about 6.4 knots (flat calm). So I can power at my target of 85 to 90% hull speed (6 to 6.4 knots) but without cooling I am running the motor at it's max temperature. With the cooling system I can run continuously at 6 knots and keep the system running in the 60-70% range I need to cool the motor.

The coolant pump is the same type as used for controller cooling in a Toyota Prius. Very simple and reliable. The raw water pump is a Jabsco Water Puppy bronze bodied impeller pump. This needs to be a robust pump since its below the waterline. I think the raw water pump moves more water than needed to take the heat away from the heat exchanger. I plan to experiment with a speed controller to slow it down a bit so it uses less power. And I would like to set the controller up to trigger two-stage cooling where it uses a different temperature profile for the raw water pump.

The boat also has a water heater for domestic hot water. It used to be heated by the cooling water from the diesel or from shore power. I may run the coolant loop to the water heater but if that water tank is already heated from shore power it may be better not to. In normal operation there may not be enough excess heat to make use of in the water heater. And if that water is already hot it may actually add heat to the motor. I'll look at this in more detail in the spring.

System diagram, the Motenergy ME1616 water cooled motor, the controller, and some of the cooling system components.