| Pearson 10M Electric Drive |

|

In late October I finished my sailing season for 2021. Total motor running time was probably about 90-100 hours. My total time logged on the water was 251 hours. Average ride was 3 hrs and I figure I motor for 1 hour total for each ride plus some additional motoring on several days of testing.

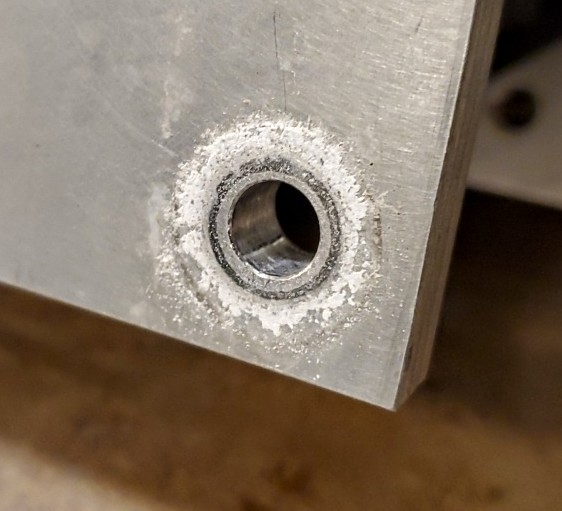

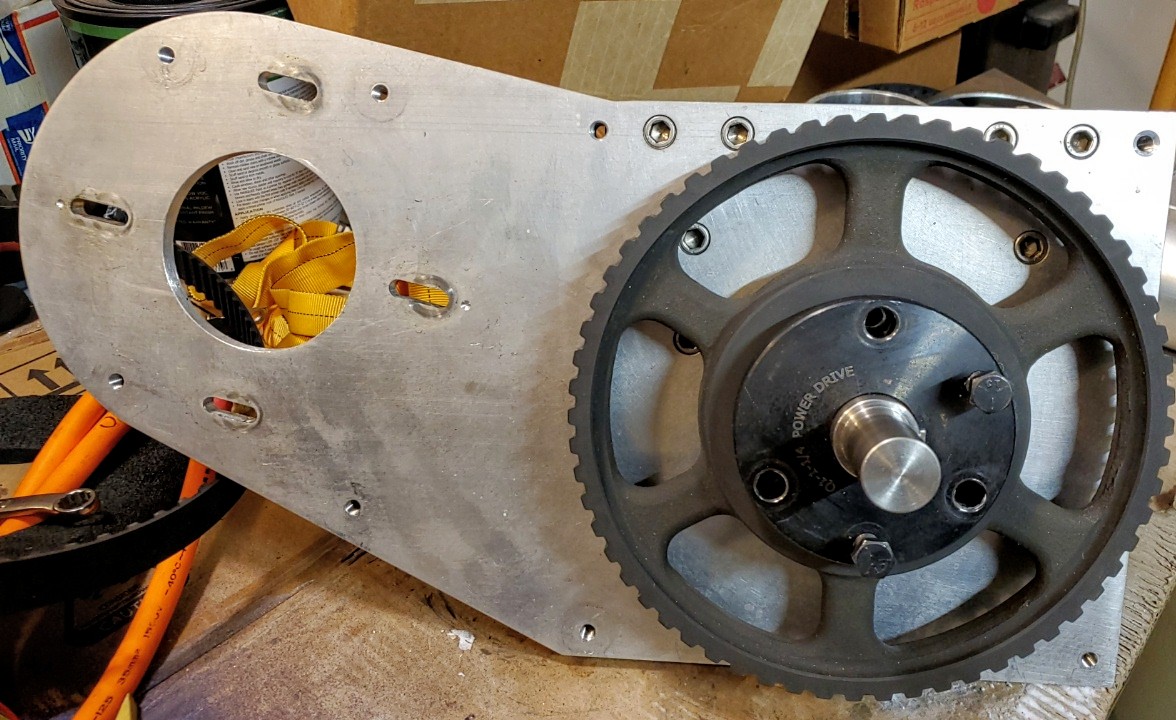

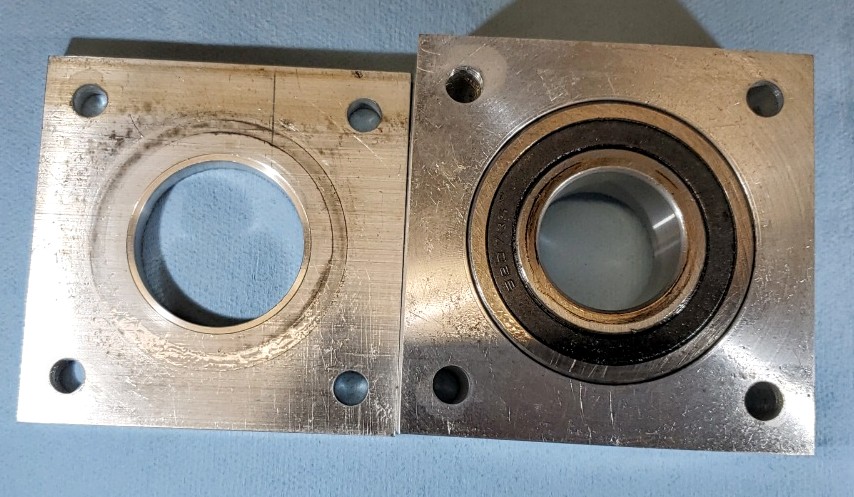

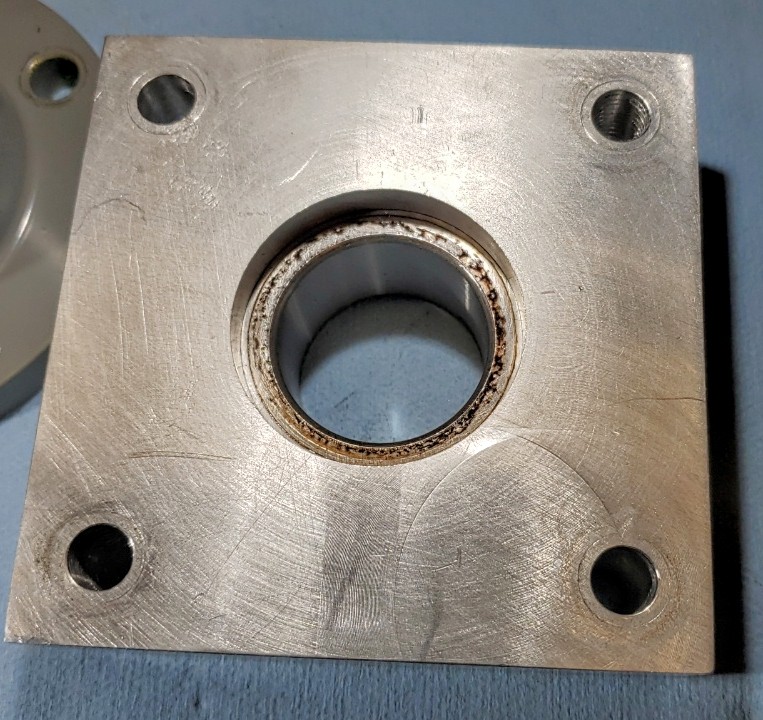

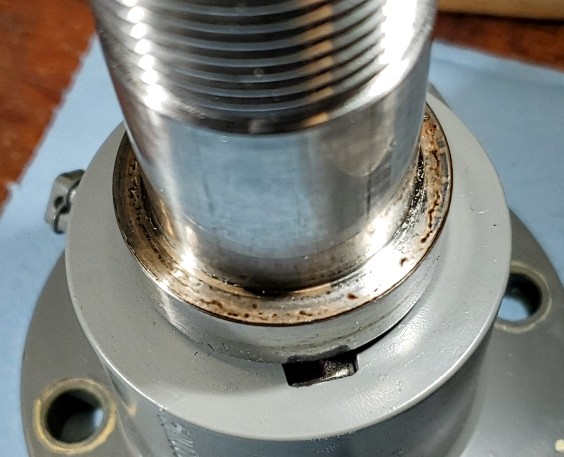

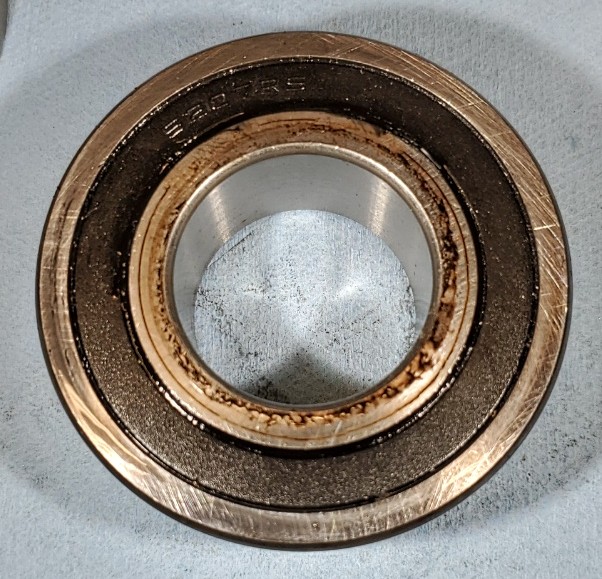

Total charging logged was 161.66 kWh for 2.046kWhr per ride. My service at home is $.0521/kWh so at that rate it works out to $8.42 total for electricity used for the whole season. The diesel would have cost $200 for the same use (at APR. $3.50/gal). Safe to say that the running cost of the electric is less than 1/10 of diesel. After fall haul out I disassembled the electric drive unit for inspection. I found some surface rust on the steel parts but everything came apart without any trouble. There was some oil residue inside the thrust bearing housing but I assembled it with some machine oil spread over all the surfaces. So I can't really tell if what I am seeing is from that or from lube leaking from the bearing seals. Seems like light oil and the bearing is lubed with grease. There was no apparent wear in the shaft or looseness of any kind anywhere. Everything was as snug as when I assembled it. The thrust bearing feels fine in the hand - smooth and true. There were no signs of binding or rubbing. Belt wear was minimal to unnoticeable. I found only a very small amount of black residue on the inner faces of the plates where the belt runs. There was some corrosion on the aluminum cover plate where I didn't properly coat the SS fasteners with Tef-Gel. Where I did use Tef-Gel everything was fine. Overall I would say everything came out in excellent shape with regard to wear but I need to attend a bit better to corrosion protection on the steel parts and where there is SS+Aluminum contact. I am glad I used SS for the shaft. I can get an SS version of the pilot bearing and I can get an SS threaded locking collar. That might be worth it to eliminate the nuisance of rust on those parts. The pulleys and their bushings will need to be coated better or painted. Maybe I'll spray then with McLube. I did that on my bronze stuffing box 18 years ago and it has held up perfectly. |

|