| Pearson 10M Jib Boom 2.0 |

|

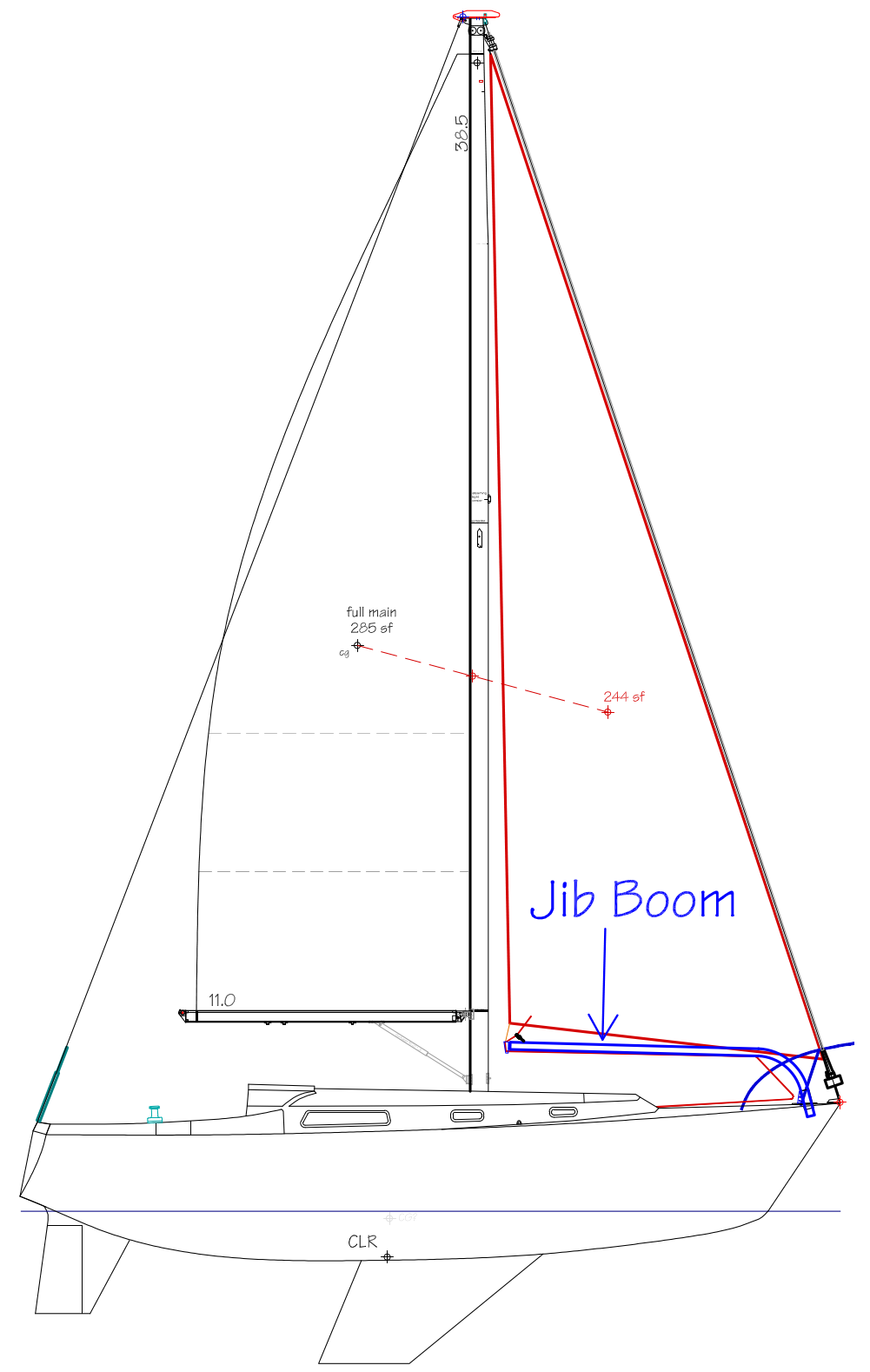

The geometry of the Forespar Hoyt jib boom was not a perfect match on my 10M. It gave some significant and proven advantage in use but pivot angle of the boom meant that in use it was giving up luff tension as the boom was eased. I fabricated a new boom to correct this and to add some additional features to enhance performance.

Results have been very good with some bumps along the way that I will detail below. The new boom is a bit heavier than the Forespar unit (maybe 65 lbs vs 40lbs ??) but the geometry is much better and performance is improved. I no longer loose luff tension as I ease the boom and I can now wing out the boom in any wind strength without Mr Gravity interfering with my plans by making the boom fall back to centerline. I do give up some upwind performance in light air to the #1 genoa but not as much as you might expect. With jib boom #1 the performance crossover point from genoa to jib was at about 14 kts TWS. Now it's more like 8? Also thanks to a new jib better optimized to fit the boom. |

|

GEOMETRY & FIT

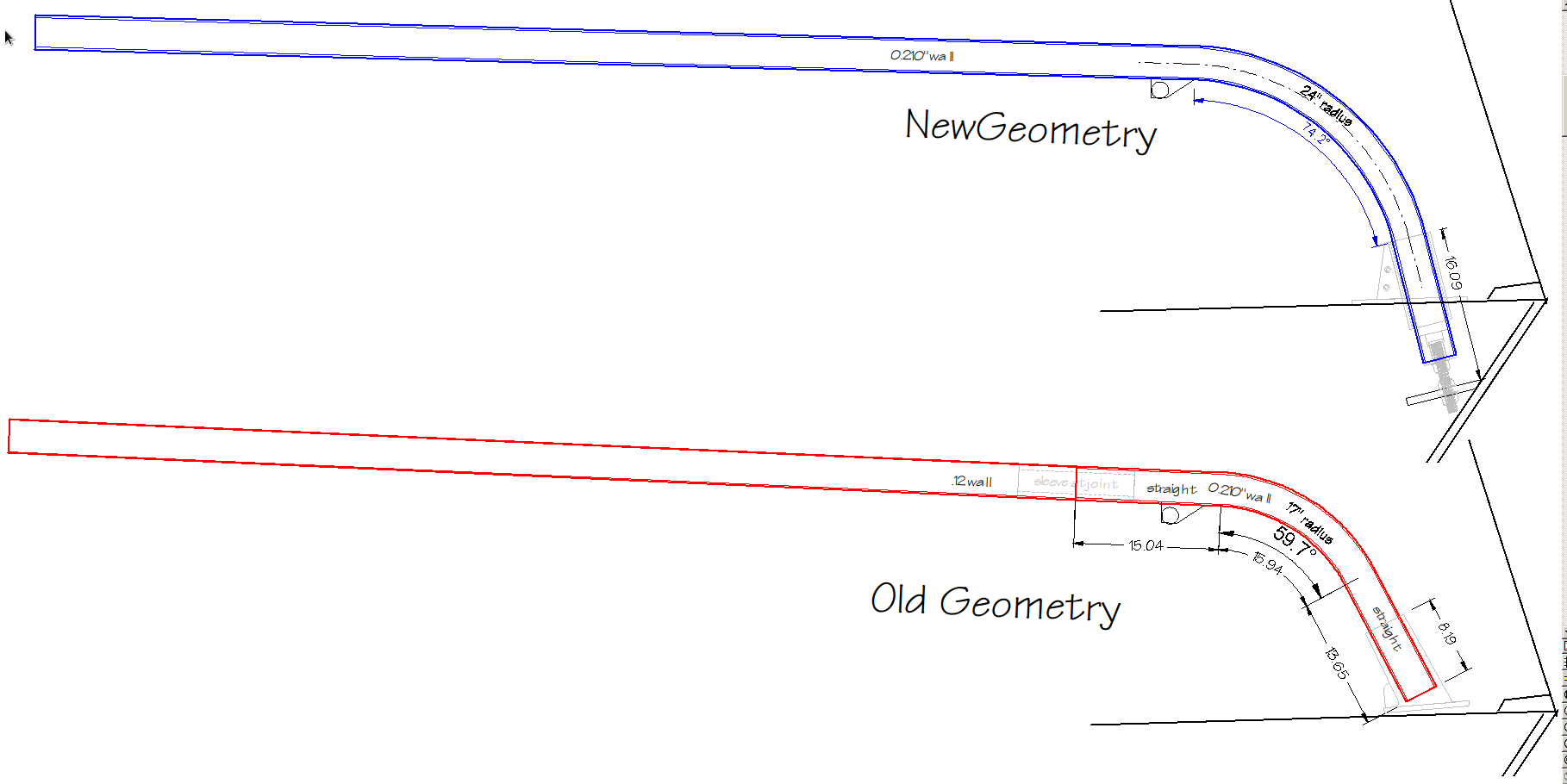

| To maintain luff tension on the jib the rotation axis of the boom should be parallel to the forestay. That way the distance from the masthead down to the end of the boom stays constant as the boom rotates. If the rotation axis is tilted aft (as with the Forespar unit) this masthead-boom end distance decreases as the boom rotates from centerline and you loose tension in the leech of the sail. I actually tilted the rotation axis forward a bit to compensate for flexing of the boom as it swings out and the sheet angle gets more extreme for holding the end of the boom down. |

|

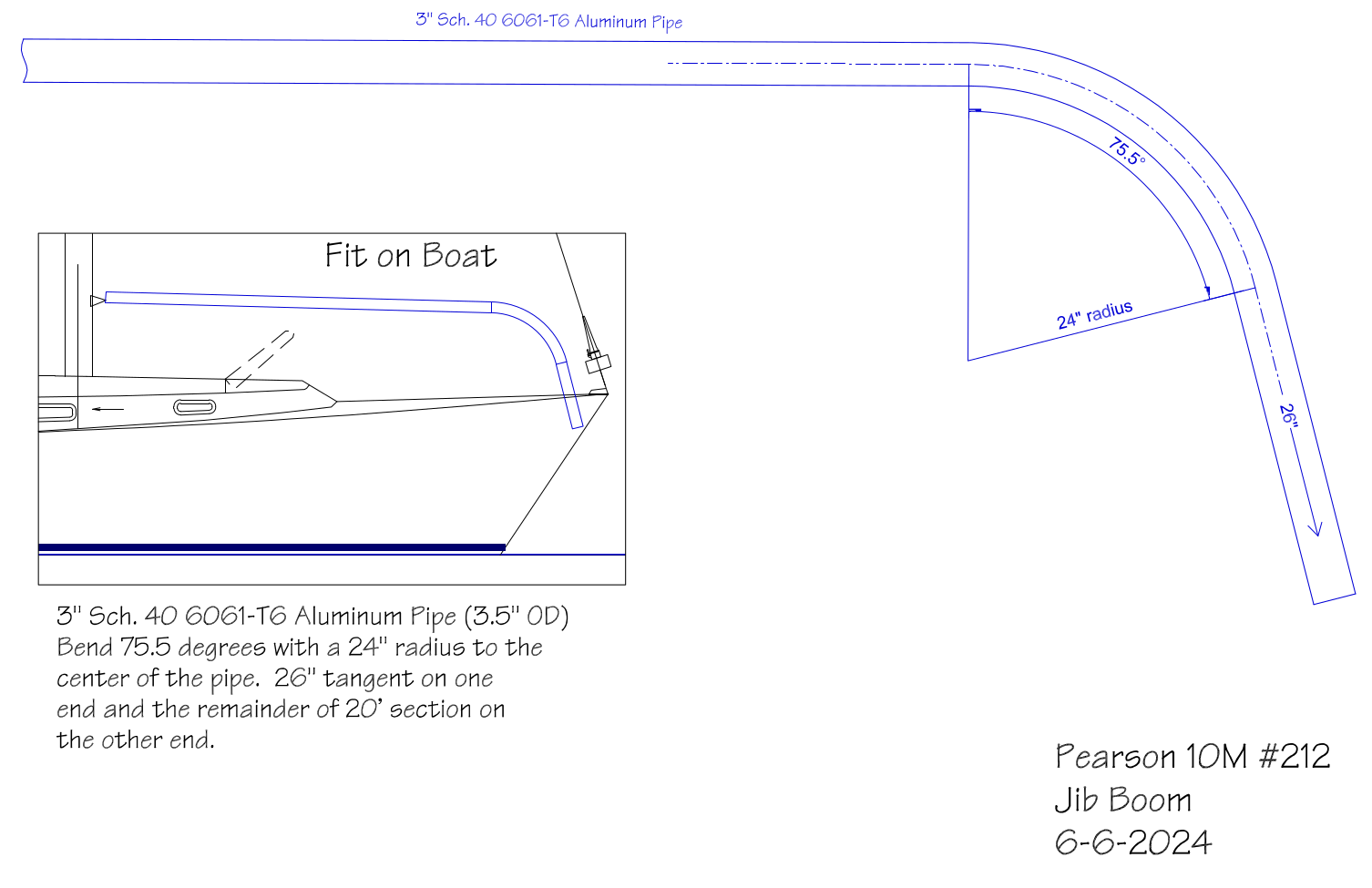

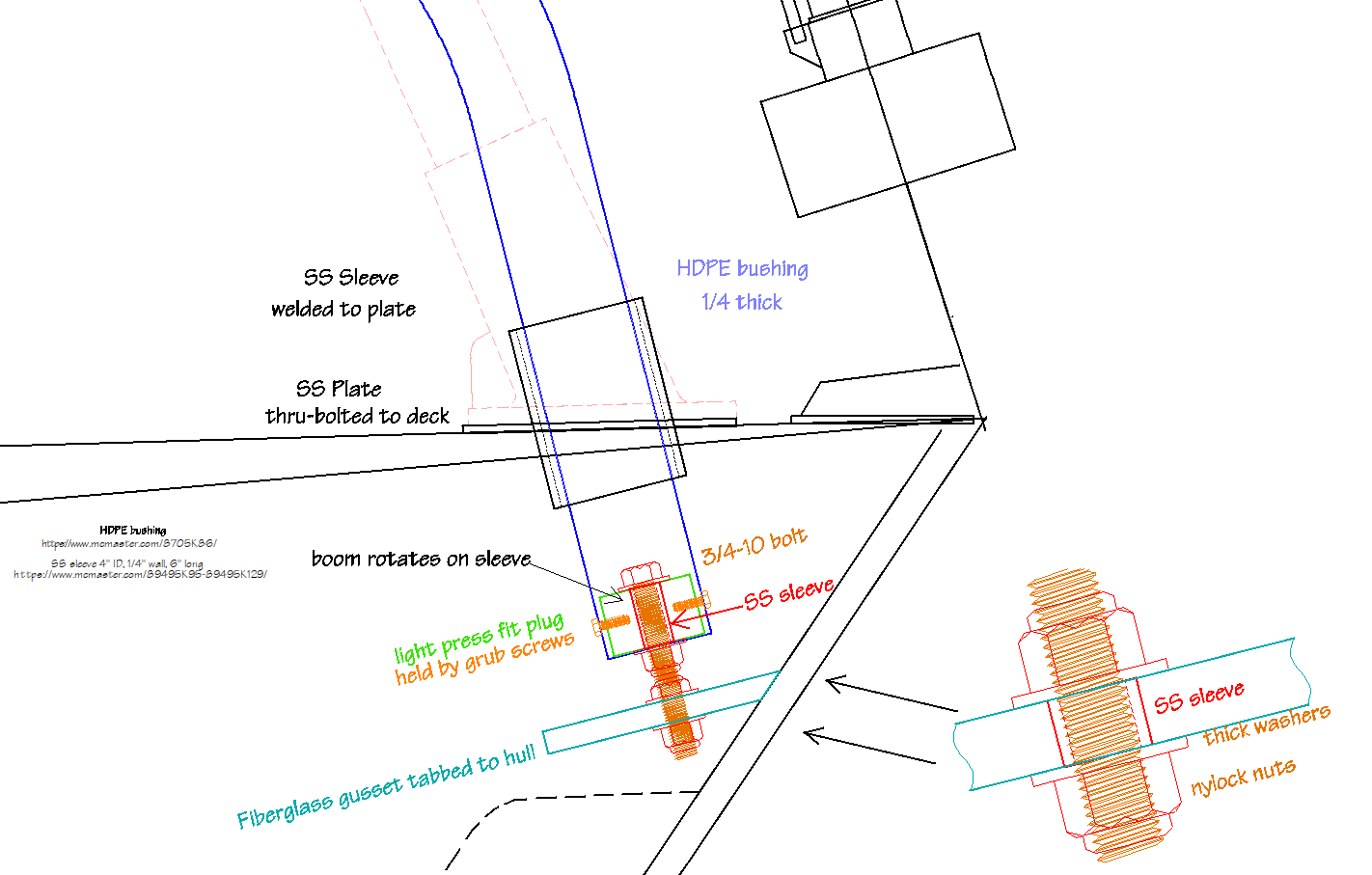

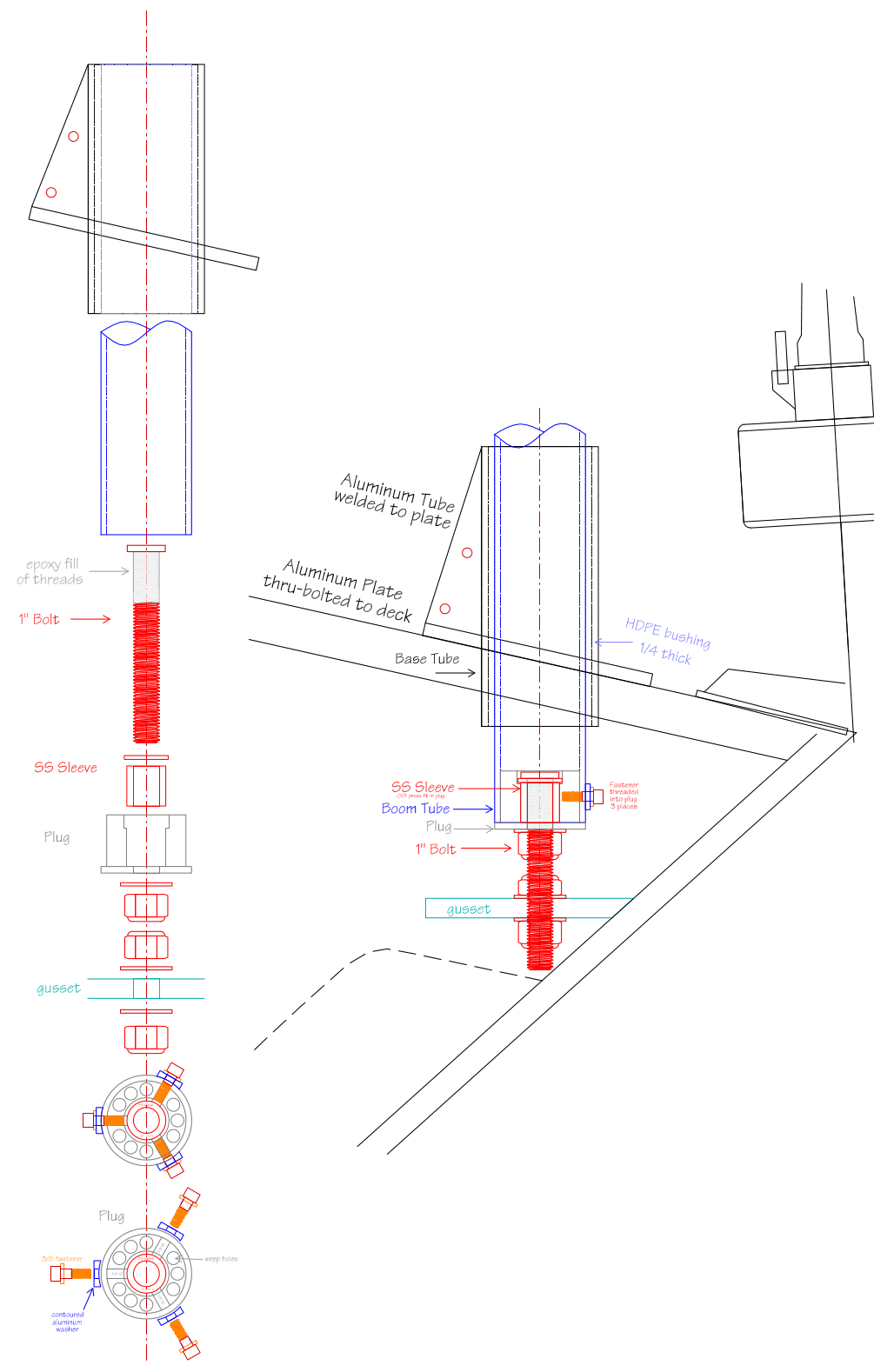

I looked to correct this by pivoting the base of the boom on a wedge but that raised the boom end too high to properly tension the leech even on centerline. I looked into adding bend to the Forespar unit but this was not practical. A new fabrication was needed. I had a length of 3" schedule 40 aluminum pipe bent at a local shop that specializes in bending. This pipe is 3-1/2" OD with 0.22 wall thickness. It's pretty husky stuff. I fabricated a new base for the boom and cut a hole in the deck so the boom extends below to an anchor point on a gusset tabbed to the inside of the hull at the forepeak. |

|

Extending the boom tube below deck made the mount stronger and reduced the bending loads on the deck. It also allows fitting a below-deck jib boom extender to hold the boom outboard. This is especially useful in light air (less than 10 kts) when gravity works against the wind holding the boom out. |

|

I fabricated a swivel assembly for the boom that fits in the end below deck. The unit is built around a 1" SS bolt that fastens to the gusset that was tabbed into the forepeak. |

|

Photos of Jib Boom 2.0 (Just the photos...)