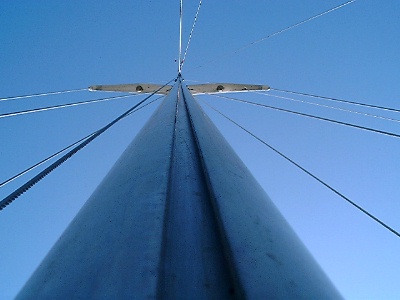

| Mast Wiring Conduit |

The 10M mast has no provisions for securing the wiring harness inside. I added a conduit made from 1" schedule 80 (thin wall) PVC pipe riveted inside the mast. 3/4" was big enough for the wires but I wanted plenty of room to for the wires and the rivets. I used aluminum rivets to reduce the potential for galvanic corrosion of the mast (stainless could result in the mast getting eaten away around the rivets) and I bedded the rivets with Tef-Gel. That means I spread Tef-Gel over the rivet before installation. I also noticed that some of my aluminum rivets had steel pins in them. After installing all the rivets I went back and popped all he steel pins out. After the conduit was in place I set the bottom of the mast down on he ground and flushed out the drilling chips and the rivet pins with a hose. I placed the conduit at the back of the mast where there was a sort of corner at the edge of the flange for the sail track.

The 10M mast has no provisions for securing the wiring harness inside. I added a conduit made from 1" schedule 80 (thin wall) PVC pipe riveted inside the mast. 3/4" was big enough for the wires but I wanted plenty of room to for the wires and the rivets. I used aluminum rivets to reduce the potential for galvanic corrosion of the mast (stainless could result in the mast getting eaten away around the rivets) and I bedded the rivets with Tef-Gel. That means I spread Tef-Gel over the rivet before installation. I also noticed that some of my aluminum rivets had steel pins in them. After installing all the rivets I went back and popped all he steel pins out. After the conduit was in place I set the bottom of the mast down on he ground and flushed out the drilling chips and the rivet pins with a hose. I placed the conduit at the back of the mast where there was a sort of corner at the edge of the flange for the sail track.

Installation Tricks

Some sources recommend drilling extra holes a couple inches away from the rivet holes so that you can take a coat hanger hook and pull the conduit against the inside of the mast for riveting. The extra hole gets filled in with a rivet. I don't like the idea of all those extra holes doing nothing and all those rivets sticking into the mast where halyards are running. I came up with another method. It worked for me you may have different luck. I drilled pairs of inline holes every 2 feet. With the mast rotated so the conduit location was at the bottom, and with the assembled conduit in place, I placed a large screw driver through the big hole for the shroud tangs to hold the conduit firmly against the inside of the mast. Then I drilled holes through the top pair of holes that were already in the mast (1" apart) and through the conduit. I took a short length of coat hanger (about 1.5" long) and bent the top 1/8" over 90 degrees and clamped he other end in my vise grips. This still fit through the holes and into the conduit. I could then hook the conduit and pull it tight against the inside of the mast. With the conduit tight I put a rivet in the first hole. With the first rivet holding the conduit down I put the second in. I needed the screw driver at the top because there was nothing to hold the conduit down. For the next pair there was no convenient hole but with the first rivet pair a couple feet away the conduit was snug enough to cut a hole in the first of the 2nd hole pair with a good sharp bit. With that hole drilled in the conduit I put in my hook, hold the conduit in place, and drill the other hole for that pair. The rivet goes in that hole then the hook comes out and a rivet goes in the other. I used rivets that were just long enough to grab the conduit with about 1/8" to spare.

Special Tools

I made two special tools for this project. One was the wire hook mentioned above to pull the conduit against the inside of the mast. The other was a drill guide template to locate the holes for the rivets. I took a T-shaped piece of plastic that came with a plumbing fitting hanging on it and bent a hook in the end (bottom of T) with the help of some heat. On the top of the T I drilled a hole so when the hook at the bottom was in the mainsail track the hole was in the right place to hold the conduit inside the mast. Once this was set I used it to mark the mast for all he hole pairs. I dimpled the surface with a center punch and used cutting oil for the holes.

Rivets holding conduit in mast

Conduit (and spiders) in the mast

Conduit in mast. You can see one rivet in the tube.